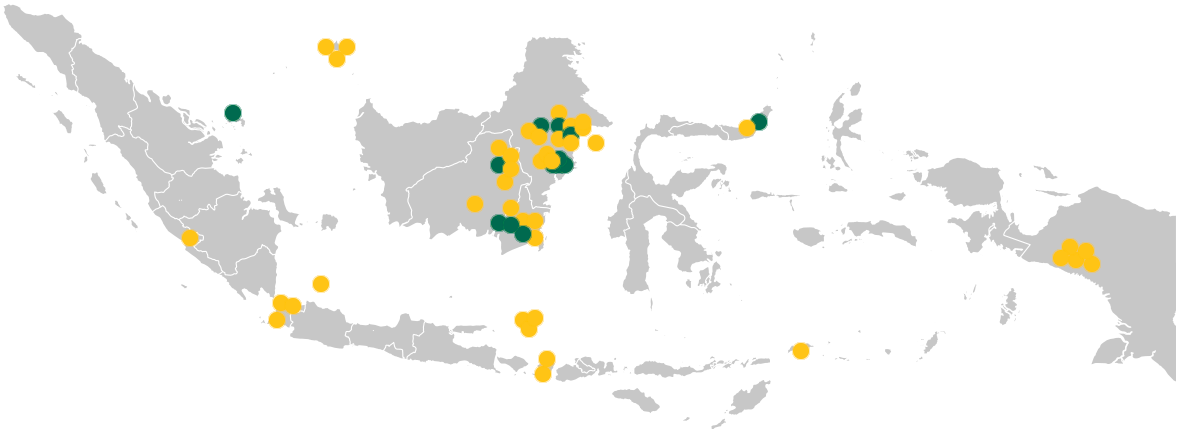

Past Major Projects

All of our accomplishments throughout Petrosea’s journey are a tangible manifestation of our various innovations to continuously improve and grow sustainably

-

Gunung Bayan Pratama Coal Project

PT Gunung Bayan Pratama Coal – South Kalimantan (1999 – 2015)

Petrosea completed work for a duration of almost 16 years to strip 30 – 55 million BCM of overburden per annum and expose clean coal at this remote mine site located at Muara Pahu, West Kutai. The stripping operations increased to suit GBP’s coal production rates which reached up to 19 strip ratios over the contract term.

-

KPC Pit K Coal Mining Contract

PT Kaltim Prima Coal – East Kalimantan (1991 – 1995)

Petrosea undertook this coal mining contract in 1991 which involved the removal of over 10 million BCM of overburden, winning and hauling of over 2.2 million tons of coal to the client’s run-of-mine hoppers. The mining operations ran 24 hours per day, with monthly rates of approximately 400,000 BCM of overburden and 100,000 tons of coal achieved.

-

BBE Contract Mining & Extension

Bukit Baiduri Enterprise – East Kalimantan (1996 – 2001)

Petrosea was awarded this three year coal mining contract for the production of 700,000 tons of coal per year. This contract involved the overburden removal as well as winning and hauling of a total of 2.1 million tons of coal from the client’s operations on the Mahakam River in East Kalimantan. In May 1999, Petrosea was awarded a three-year contract extension to mine and haul overburden and coal.

-

Tunu Field Development Phase VII

Total Indonesia – East Kalimantan (1998 – 2001)

This project included engineering, procurement, construction and installation of offshore platforms and pipelines for Phase 7 Willy Jezede at the Tunu Field, located on the outer margin of the Mahakam River. The scope of work included EPCIC work for trunkline networks, as well as the modification of Gathering and Testing Satellite (GTS) platform pipework. All trunklines were buried as 2m in offshore areas and 1.3m in swamp areas, with approximately 16km of the trunklines located in swampy areas.

-

Floating Gold Processing Plant

Minproc Engineers (SEA) Pte Ltd. – Central Kalimantan (1987 – 1988)

Petrosea was awarded this contract to develop a floating gold processing plant at Kasongan, Central Kalimantan. The fabrication, assembly and testing of the plant were executed at Petrosea’s Singapore regional workshop and waterfront facilities. On completion, the barge-mounted plant was towed up the Katingan River to the Kasongan alluvial gold deposit and subsequently commissioned.

-

KPC Diesel Fuel Line

PT Kaltim Prima Coal – East Kalimantan (1997 – 1998)

During this project, Petrosea undertook complete electrical design and procurement, construction, testing as well as commissioning associated with the automation of a fuel pipeline in East Kalimantan. The pipeline transported diesel fuel from the port facility at Tanjung Bara to diesel storage tanks at the Sangatta run-of-mine (ROM) Diesel Storage Yard operations, with a distance of approximately 16km. All design and installation works were completed to Australian Standards.

-

Bontang Coal Marine Wharf Works

PT Indominco Mandiri – East Kalimantan (1998 – 1998)

This project was granted by Indominco as a key part in the capacity expansion of the client’s coal mining operations in East Kalimantan. The piles splicing, precast concrete and structural steel were all fabricated at Petrosea’s Tanjung Batu facility and then shipped by barge 300km north to the site for installation.

-

Adaro Kelanis Upgrade

PT Adaro Indonesia – East Kalimantan (1994 – 1995)

Petrosea was awarded this project to upgrade coal stockpile and load-out facilities for PT Adaro Indonesia at their coal mining project in Central Kalimantan. The scope of work consisted of material supply, labour, equipment, tools and supervision for all construction activities.

-

IMK Gold Plant Facilities Development

PT Indo Muro Kencana – Central Kalimantan (1995)

This project was located around 600km up the Barito River with the nearest town being four hours away by boat. The processing plant had a capacity of approximately 1.2 million tons of ore per annum. This project incorporated all civil, structural, fabrication, piping and building works, mechanical equipment and installation, as well as electrical works. At the peak of construction, this project employed over 600 local personnel.

-

Tanjung Bara Coal Terminal

PT Kaltim Prima Coal – East Kalimantan (1989 – 1991)

Petrosea, through a joint venture partnership, was awarded a contract for the design, procurement, construction and commissioning of the Tanjung Bara Coal Terminal. The terminal formed a major part of the infrastructure associated with PT Kaltim Prima Coal’s 7 metric tons per annum coal mine located at Sangatta, East Kalimantan.

-

Pagerungan Inlet Compression Facilities

Atlantic Richfield Bali North Inc. (ARCO) – Pagerungan Besar Island (1997 – 1999)

This substantial engineering, procurement and construction contract continued Petrosea’s involvement with the facility which we originally built for ARCO seven years earlier. The contract involved all facets of development, from design, procurement and fabrication to the installation and start-up of two new trains, each with a capacity of 500 million standard cubic feet per day (MMSCFD), designed to significantly boost production capacity.

-

Pagerungan Besar Gas Field Development Phase 2

Atlantic Richfield Bali North Inc. (ARCO) – Pagerungan Besar Island (1991 – 1993)

This EPC contract was for a major gas field development project on Pagerungan Besar Island. Stage 1 (engineering) was completed by a dedicated project office established in Perth, Western Australia, while Stage 2 (procurement & construction for a gas processing plant, accommodation village, airstrip, tankage, harbor and all associated support works) was controlled from a project management office in Surabaya and project offices in Jakarta.

-

Amamapare Cargo Wharf

PT Freeport Indonesia – Papua (1993 – 1994)

In just nine months, Petrosea completed the new Amamapare cargo wharf, employing around 600 personnel located both on-site at Papua and at Petrosea’s Tanjung Batu fabrication yard in East Kalimantan. The 260m by 18m wharf space frame structure was fabricated at Tanjung Batu in six separate modules. Some 2,000 tons of structural steel was utilized in the wharf module structures and ancillary fabricated items. The modules were loaded onto barges and shipped to Papua for installation.

-

Amamapare Bridge Construction

PT Freeport Indonesia – Papua (1993)

Petrosea was awarded this contract to design and construct two 120m long by 9m wide traffic bridges to carry heavy haulage freight vehicles from the newly developed Amamapare port to the mine site. The bridges were designed to withstand the twin-engine equipment mover with a pay load of 180 tons.

-

Timika Airstrip Upgrade

PT Freeport Indonesia – Papua (1991)

Petrosea was awarded this contract to upgrade a remote airstrip owned by PT Freeport Indonesia in Timika, Papua. The scope of work included the expansion of the airstrip by widening and lengthening it to cater for Boeing 737 and 757 aircrafts, asphalt resurfacing of the entire runway, apron and taxiways and line markings for the resurfaced pavements.

-

Santan Batubara

PT Santan Batubara – East Kalimantan (2009 – 2016)

PT Santan Batubara was a joint venture company owned by Petrosea and PT Harum Energy, with each owning 50% of its shares, located in an area of 24,930 ha in Kabuparen Kutai Kartanegara, East Kalimantan. First production commenced in March 2009, in which PT Santan Batubara successfully produced 1.25 million tons of coal during its first year. The target was to produce 3 million tons of coal per annum for the years 2011 until 2014.

-

DEJ Rantau Bakula Block V Coal Mining Contract

PT Dasa Eka Jasatama – South Kalimantan (2001 – 2002)

Starting in 2001, Petrosea, in a Joint Operation (JO) with PT Pamapersada Nusantara, conducted a four year contract to strip and mine 6.4 million coal and transport the it approximately 35 km to a coal blending stockyard and another 71 km to a barge loading facility on the Barito river. The JO was responsible for controlling all aspects of the mining operations to initially produce 1 million tons of specified quality coal per year to fulfill DEJ’s sales into both the domestic and export coal markets.

-

Sanga Sanga Coal Mining

PT Sanga Coal Indonesia – East Kalimantan (2003 – 2009)

Petrosea was awarded this four year mining services contract by PT Mitra Internusa Persada. The contract was to mine over 50 million BCM of overburden and 5.7 million tons of coal at the Sanga Sangat coal concession, located near Samarinda in East Kalimantan, approximately 90 KM north of Balikpapan. The scope of work included clearing of land, overburden removal, overburden stripping, mining and hauling. The mine itself was expected to produce 1.5 million tons of coal per annum.

-

ABN Overburden Removal

PT Adimitra Baratama Nusantara – East Kalimantan (2009 – 2015)

In 2009, Petrosea signed a 60-month mining contract with ABN located 5 KM from Petrosea’s previous operations at Sanga Sanga. The scope of work included excavation, removal, loading and hauling of total 39 million tons of coal and 568 million BCM of overburden.

-

Bontang Coal Terminal Upgrade Project Stage 2

PT Indominco Mandiri – East Kalimantan (2007 – 2010)

Petrosea, together with Laing O’Rourke, was awarded this contract for engineering, procurement, construction and installation work at the Bontang Coal Export Terminal owned by PT Indominco Mandiri. The EPC scope of work included upgrading and modifying existing conveyors as well as provision of new barge loading facilities and conveying systems. Through this project, the coal terminal’s capacity was increased to an ultimate 18 metric tons per annum.

-

Bumbun Camp Construction

PT Juloi Coal (BHP Billiton Indonesia) – Central Kalimantan (2007 – 2008)

Petrosea’s scope of work for this project included a 250-man camp equipped with a fly-in and fly-out heliport area maintenance hangar, water / sewage treatment plant, clinic, main office, induction room, mosque, in-camp access road, walkway as well as industrial area (fuel storage, workshop, main power station and other storage areas).

-

Pakar Coal Mine Development Project

PT Ilthabi Bara Utama – East Kalimantan (2007)

Petrosea worked in alliance with PT Ilthabi Bara Utama to perform works for the Pakar Coal Development Project, an open cut coal mine in East Kalimantan which produced thermal coal for both export and domestic consumption. Under the alliance agreement, the project team was responsible for the design, procurement and construction of the mine infrastructure facilities, including haul road, stockpiles and material handling facilities at both the mine and port locations.

-

KPC Coal Handling Upgrade – Civil Works

PT Roberts Schaefer Soros Indonesia – East Kalimantan (2004 – 2005)

Petrosea was awarded this contract for earthworks and concrete structures to upgrade the existing coal handling system owned by PT Kaltim Prima Coal at Sangatta, East Kalimantan. The scope of work included construction of the truck dump area, dump hopper slab and paved area, a new stockpile area and reclaim tunnel including head and wing walls, new overland, conveyor and surge bin foundations, as well as a Mechanically Stabilized Earth (MSE) wall.

-

Namuk Tailings Dam Complex Final Closure

PT Kelian Equatorial Mining – East Kalimantan (2004 – 2005)

Petrosea was awarded this project in preparation for closure of the gold mine operations owned by PT Kelian Equatorial Mining (subsidiary of RioTinto) located in East Kalimantan. The scope of work included the enlargement and modification of the existing tailings dam and construction of a new emergency spillway. It also included the installation of monitoring equipment, both within and around the embankment together with the upgrade and construction of access roads.

-

West Seno Deepwater Facilities Project

Unocal Corporation – East Kalimantan (2001 – 2003)

Petrosea, together with Laing O’Rourke, was awarded this contract for engineering, procurement, construction and installation work at the Bontang Coal Export Terminal owned by PT Indominco Mandiri. The EPC scope of work included upgrading and modifying existing conveyors as well as provision of new barge loading facilities and conveying systems. Through this project, the coal terminal’s capacity was increased to an ultimate 18 metric tons per annum.

-

Kerisi Field Development Project – Construction of Offshore Flowline System

ConocoPhillips Indonesia Inc.Ltd. – Natuna Sea (2005)

This contract involved project management and engineering for the construction of approximately 50km of 12” and 16” diameter oil & gas pipelines, plus fabrication and installation of five subsea structures weighing up to 150 tons. The pipelines tied into a Floating, Production and Storage Offloading (FPSO) vessel, located in a water depth of 90m in the Belanak Field. Project management and engineering activities were undertaken at Petrosea’s head office in Jakarta and offshore installations were carried out utilizing Clough Limited’s offshore derrick lay barge, “Java Constructor”.

-

Gajah Baru Gas Export Project

Premier Oil – Natuna Sea (2002)

This project was for modifications to the existing Anoa-AGX Gas Compression Platform located in the Natuna Sea. The scope of work included the design, supply, fabrication and installation of a new platform for gas production and processing with compression facilities as well as construction and commissioning of a 3km export pipeline between Gajah Baru and the existing WNTS system.

-

Otomona Bridge Upgrade

PT Freeport Indonesia – Papua (2003 – 2004)

Petrosea undertook the construction of a new 100 meter long bridge at Otomona, Timika, Papua, owned by PT Freeport Indonesia. The scope of work for this project included the fabrication of a structural steel trussed bridge, approach trestles and piled foundations, relocation of an existing road and pipelines, as well as the removal and dismantling of the existing bridge.

-

Babo Airstrip Upgrade

BP Berau Ltd. – Papua (2003)

Petrosea was awarded this contract to upgrade a remote World War 2 airstrip in Babo, Papua, as the first regional development of BP Tangguh Ltd. The scope of work included the detailed design, procurement, construction and commissioning of the airstrip and helipad as well as associated facilities, such as a terminal building complete with a hangar and control tower as well as a floating pontoon berth for crew boats.

-

Cikokol Water Treatment Plant

PDAM Tirta Kerta Raharja – West Java (2004 – 2013)

Petrosea, through its 47% equity interests in PT Tirta Kerta Cahaya Mandiri (TKCM), entered into a cooperation agreement with PDAM Tirta Kerta Raharja, a regional municipal water company, owned by the local government in the regency of Tangerang, Banten. From the first day of operations in November 2004 until December 2013, the Cikokol Water Treatment Plant successfully pumped and sold a total of 339.2 million m3 of quality drinking water to PDAM TKR.

-

Cibaliung Gold Project, Detailed Engineering & Procurement Services

PT Cibaliung Sumberdaya (Austindo Resources Corp NL) – West Java (2005 – 2007)

Petrosea undertook a range of continuous contracts for construction and infill engineering works during the relocation of the gold process plant from Mount Olympus Gold Plant at Paraburdoo, North Western Australia to Cibaliung, West Java. The Cibaliung Gold Process Plant comprised of a single stage primary jaw crusher, sag mill grinding, two stages of leaching followed by seven stages of CIL carbon stripping in elution electrowinning and dore smelting with plant throughput of 220,000 tons per annum.

-

APN Field Development

BP Indonesia – West Java Sea (2004 – 2005)

This engineering, procurement and construction contract included design, fabrication and installation of three unmanned offshore monopod structures that were linked by 28km of 24″ diameter in-field pipelines, brownfield tie-ins to existing facilities, major compressors re-configuration, mechanical completion, commissioning and start-up assistance. The APN Field was located approximately 100km north-east of Jakarta off the coast of Java in water depths ranging from 15m to 45m.

-

Uskap Coal Project

PT Santan Batubara – East Kalimantan (2012 – 2016)

As part of the Santan Batubara expansion, in July 2012 Petrosea was awarded a mine services contract by PT Santan Batubara for the excavation and removal of 5.6 million tons of coal and 85 million BCM overburden.

-

Indomining Overburden Removal

PT Indomining – East Kalimantan (2015)

Indomining appointed Perosea to conduct mining services, including overburden and plant hire in its area located beside the ABN project, in which Petrosea had been working since 2009.

-

IAC Overburden Removal

PT Indoasia Cemerlang – East Kalimantan (2015 – 2017)

On 16 October 2015, Petrosea and PT Indoasia Cemerlang entered into an overburden removal agreement at the Kintap mine area in South Kalimantan with a contract duration of one year. In October 2016, Petrosea signed an agreement amendment which included a contract extension and addition production volume.

-

ANZ Coal Project

PT Anzawara Satria – South Kalimantan (2016 – 2019)

On 11th January 2016, Petrosea and PT Anzawara Satria (ANZ) entered into an overburden removal agreement in area ANZ, Tanah Bumbu, South Kalimantan for a contract duration of three years until 2019. The scope of work included overburden removal, hire of mobile plant & personnel and coal hauling.

-

BMB Waste Removal & Coal Production

PT Binuang Mitra Bersama Blok Dua – South Kalimantan (2018 – 2020)

In May 2016, Petrosea and PT Binuang Mitra Bersama Blok Dua entered into agreement for mining services as well as heavy equipment rental and provision of personnel.

-

Lampunut Road, Bridge and Earthworks Construction

PT Maruwai Coal – Central Kalimantan (2016 – 2019)

In June 2017, Petrosea and PT Maruwai Coal entered into a construction contract for Lampunut road, bridge and earthworks construction in East Kalimantan with a contract duration of 2 years.

-

Construction of Coal Haul Road 69km & Bridges Work

PT Indonesia Pratama – East Kalimantan (2015)

Petrosea signed the contract for this coal hauling road project from Senyur port to the Tabang coal mine owned by PT Indonesia Pratama. The scope of work included but was not limited to widening, gravel replacement, grade flattening and other associated works.

-

Crane Replacement & Wharf Works

PT Indonesia Bulk Terminal – East Kalimantan (2014)

Petrosea signed a contract with PT Indonesia Bulk Terminal for detailed engineering design, logistics and construction works for the removal and replacement of the old cranes as well as refurbishment of the wharf fender system, including related works on the wharf structure.

-

Orica PMC

Orica KNI – East Kalimantan (2014)

Petrosea provided project support services to the KNI – Orica management team to monitor work performed by its main contractor, PT Rekayasa Industri, sub-contractors, vendors and suppliers, including reviewing and providing expert advice and comments on proposed procedures, methods, designs and recommendations.

-

ABN Workshop Facilities Extension

PT Adimitra Baratama Nusantara – East Kalimantan (2013)

Petrosea engaged to construct a workshop extension and facilities at the ABN project site, with the scope of work including Engineering, Procurement and Construction (EPC) for a workshop extension, mine office, mezzanine office, new lube station, new HV wash pad, waste and hazardous storage as well as fuel station.

-

MUTU Mine Infrastructure Development (Engineering Services)

PT Multi Tambangjaya Utama – Central Kalimantan (2013)

Petrosea signed a contract of work for detailed engineering design and survey support for the upgrading, enhancing capacity and debottlenecking of mine infrastructure for a coal mine site in Central Kalimantan owned by PT Multi Tambangjaya Utama (MUTU).

-

IBT Sea Conveyor Repair & Reconstruction

PT Indonesia Bulk Terminal – South Kalimantan (2015 – 2016)

Petrosea signed this EPC contract with PT Indonesia Bulk Terminal to repair the B1 and 11 conveyors which structures were damaged after being hit by an unknown coal barge. The scope of work for this project included delivery and replacement of the crane as well as other construction work.

-

Assessment, Repair & Reconstruction for IBT Coal Export Jetty

PT Indonesia Bulk Terminal – South Kalimantan (2016)

Petrosea conducted engineering, procurement and construction work for the assessment, repair and reconstruction of a damaged PT Indonesia Bulk Terminal coal export jetty on Pulau Laut, South Kalimantan. Petrosea achieved practical completion one week ahead of the baseline schedule.

-

Lampunut North Road Stage 1 Construction

BHP Billiton Indonesia – Central Kalimantan (2015 – 2016)

In 2017, Petrosea was awarded a contract by PT Maruwai Coal (BHP Billiton) for the Lampunut Road, Bridge and Earthworks Construction project to construct the access road to the Lampunut coal project in Central Kalimantan.

-

Civil Concrete Utilities & Infrastructure Works

PT Maruwai Coal – Central Kalimantan (2018 – 2019)

In December 2018, Petrosea received a Notice of Award from PT Maruwai Coal for civil concrete utilities & infrastructure works.

-

Civil Works for Re-Location of MCCP B Line to SMCP Area

PT Kideco Jaya Agung – East Kalimantan (2019 – 2020)

In June 2019, Petrosea & PT Kideco Jaya Agung entered into an agreement for civil works for the relocation of MCCP B-Line to SMCP area.

-

Infrastructure Works Stage 1

Multi Tambang Jaya Utama (MUTU) – Central Kalimantan (2019 – 2020)

In October 2019, Petrosea was awarded a contract by PT Multi Tambangjaya Utama (MUTU) for the hauling road upgrading and coal handling facility project. On January 19, 2020, Petrosea received a certificate from PT Multi Tambangjaya Utama for the completion of the ROM Aster infrastructure project.

-

Vale Design & Contruction Core Facilities

PT Sumbawa Timur Mining – Bima & Dompu, NTB (2018 – 2019)

In December 2018, Petrosea was awarded a contract by PT Sumbawa Timur Mining for the design & drawing, soil investigation and construction of core facilities.

-

EPCM of Refeed Conveyor and Conveyor Extension

PT Newmont Nusa Tenggara – West Nusa Tenggara (2016)

Petrosea was awarded this nine month contract by PT Newmont Nusa Tenggara for engineering and construction management services to engineer, construct and install a material re-feed conveyor, including an extension to the existing conveyor in order to increase mill capacity and improve utilization of the existing pebble crushers.